Transformative Environmental Pieces

Blaine Hafen

Industrial Design, 2022

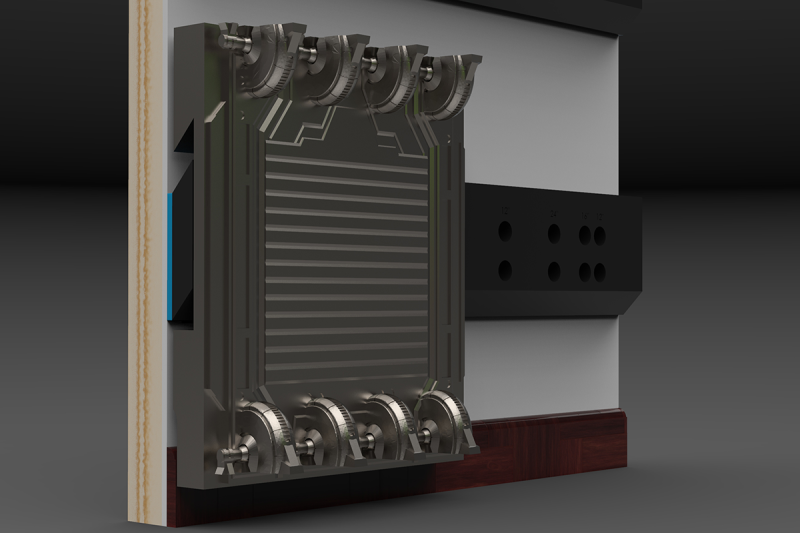

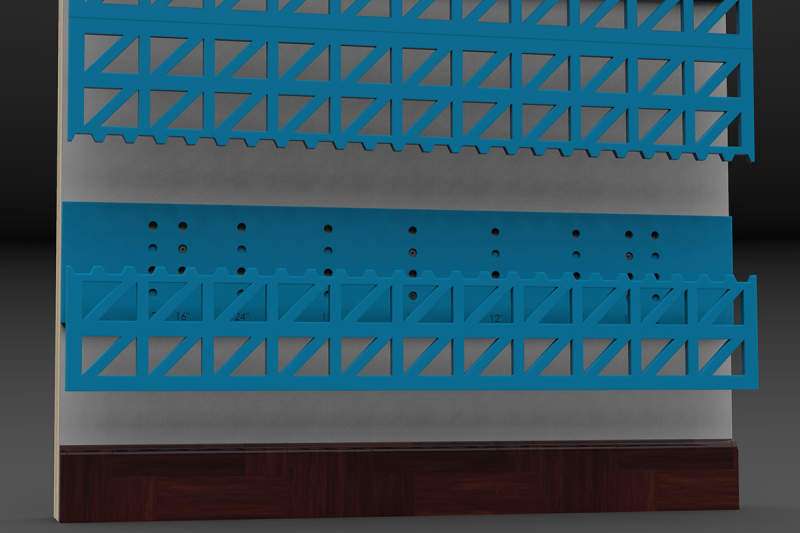

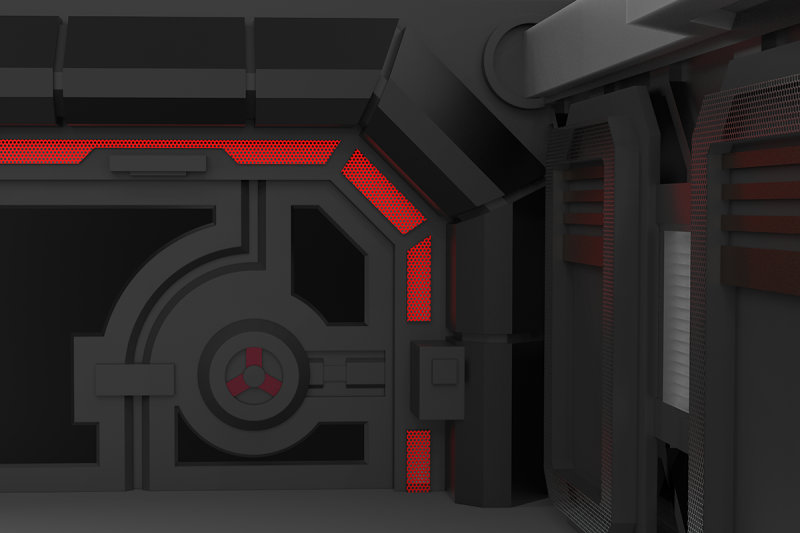

This project was a collaboration between the Department of Design, Cincinnati Inc, and CDME. The project aims to empower immersive spaces (retail, theme parks, museums, etc) with the ability to rapidly transform their spaces. This is achieved by utilizing Cincinnati Inc’s large scale additive manufacturing machines (3D printers) to rapidly print panels that can easily be installed and removed on a modular system that is also printed on the same machine.

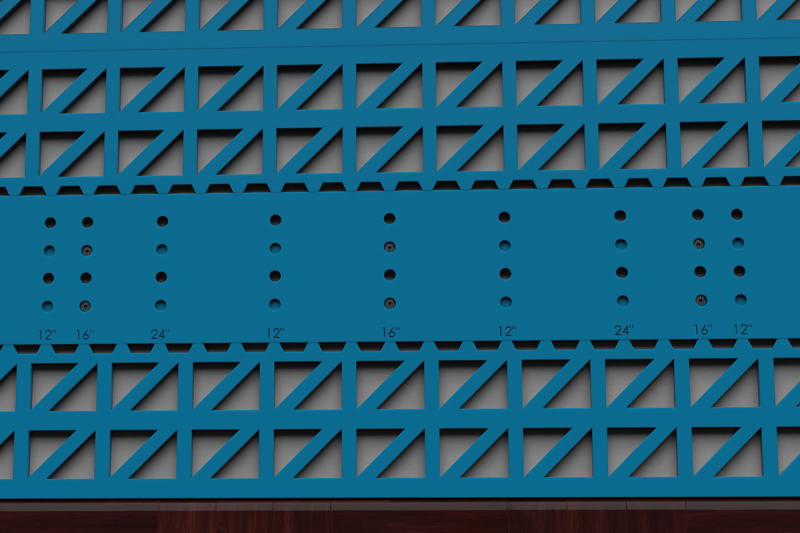

The modular mounting system works through predrilled guide holes for most wall stud spacing. A TPU (flexible plastic) layer is first mounted to create proper spacing between the cleats. Then a cleat is installed directly on the TPU. Afterwards, portions of the TPU can be removed for recycling. Environmental panels can then be dropped on the cleat. This flexibility would allow retail spaces to create an array of environments transforming consumers experiences with continued visits.

Blaine Hafen is a 3D printing nerd. He has been using the technology for over 8 years and was thrilled to use it on such a scale for his senior thesis. In the future, Blaine hopes to continue his design career as a UI/UX designer with anticipation of going to grad school to study HCI.

View Blaine's other work at here!